Tieckpak's proto-mold services are designed to meet the specific needs of product development projects. With our expertise in mold design and manufacturing, we can produce molds that accurately replicate the desired product geometry, including intricate details and complex features. These molds are created using advanced materials and manufacturing techniques, ensuring durability and longevity throughout the prototyping process. Traditional mold making process can be expensive and time consuming, often requiring extensive tooling and setup. However, our expertise and streamlined manufacturing process allow for rapid proto-mold production, significantly reducing the lead time and enabling faster iteration cycles in the product development timeline.

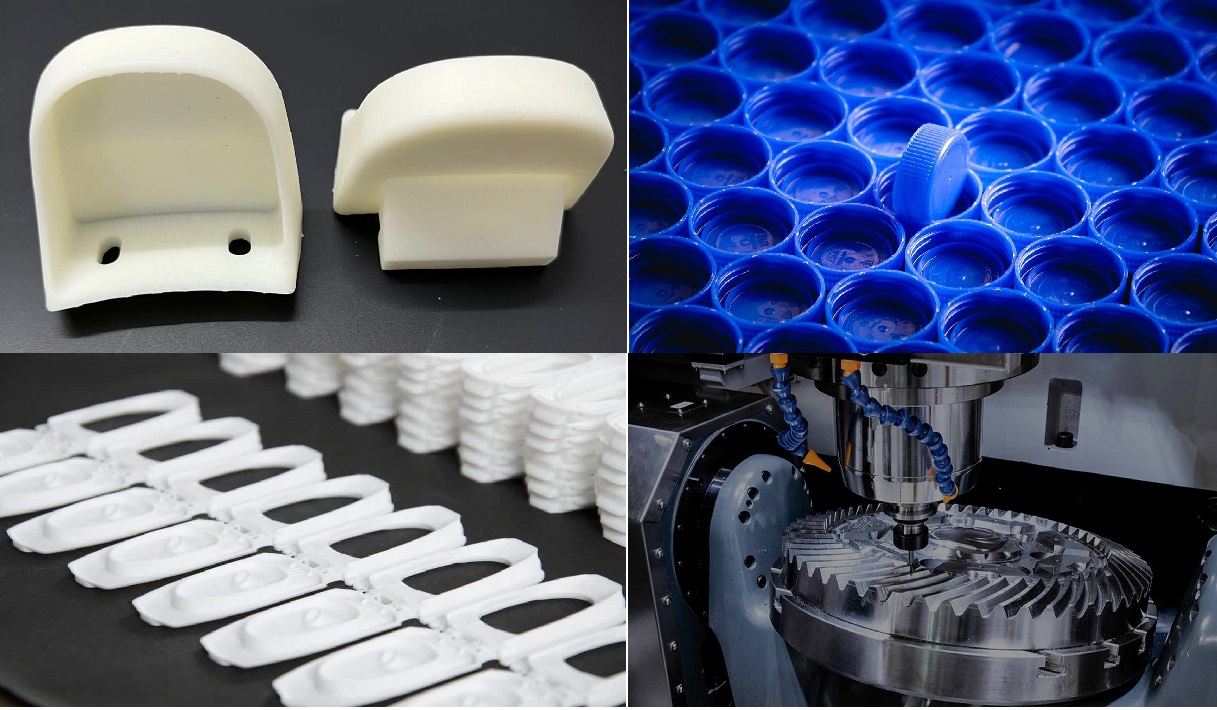

Tieckpak's mock-up parts are renowned for their quality and attention to detail. The company employs skilled craftsmen and cutting-edge technologies to ensure that every aspect of the mock-up part accurately reflects the intended design. From the surface finish to the functionality, Tieckpak strives for excellence, delivering mock-up parts that meet the highest standards of precision and aesthetics. Our mock-up parts replicate the form, fit, and function of the finished item, providing manufacturers with a realistic representation of their design concept. These parts contain advanced materials and manufacturing techniques to ensure accuracy and precision. Whether it's a complex mechanical component or a sleek consumer product, Tieckpak's mock-up parts capture the essence of the intended design. Our top-notch mock-up parts aid in validation process of any product design.

Batch production of components is a critical manufacturing process that allows for the efficient and cost-effective production of a large number of parts. We specialize in innovative manufacturing solutions, excels in batch production, delivering high-quality components to meet the demands of various industries. Our expertise in batch production enables us to optimize the manufacturing process, resulting in consistent and precise components. By leveraging advanced technologies and automation systems, we ensure efficient production runs with minimal downtime, allowing for faster turnaround times and increased productivity. Our focus on efficiency, quality control, cost-effectiveness, and customization enable us to deliver high-quality components that meet the specific requirements of our clients. With our batch production capabilities, businesses can streamline their manufacturing processes, increase production output, and achieve their goals efficiently.