Prototyping is an early sample or model of a product that is built to test the concept process. It’s typically used to validate the product design and functionality. We offer several types of prototyping viz Fused Deposition of Modeling(FDM), Stereolithography(SLA) and Vacuum Casting. We offer excellent accuracy and resolution, allowing for intricate details and fine features to be incorporated into the object.

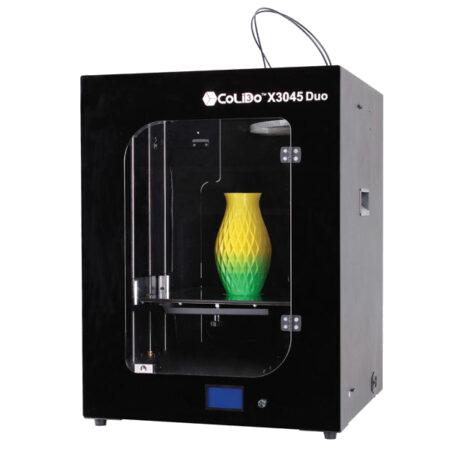

At Tieckpak FDM lies a simple yet ingenious process. It begins with a computer-aided design (CAD) file that is sliced into thin layers. These layers serve as a blueprint for the printer, which then builds the object layer by layer. The key component of FDM is the thermoplastic filament, typically made of materials like ABS or PLA, which is fed into the printer. The filament is heated to its melting point and extruded through a nozzle onto the build platform. As it is extruded, the material fuses and solidifies, creating a strong and durable structure. One of the greatest advantages of FDM is its versatility. It can accommodate a wide range of materials, allowing for various properties like flexibility, strength, and temperature resistance. This versatility makes FDM suitable for applications in industries such as aerospace, automotive, healthcare, and consumer goods. our FDM process is very cost-effective. The materials used in FDM are relatively inexpensive compared to other 3D printing technologies.

SLA process begins with a digital 3D model created using computer-aided design (CAD) software. This model is then sliced into thin layers, with each layer serving as a blueprint for the printer. The printer uses a laser to trace the shape of the object onto the surface of a vat of liquid photopolymer resin. Where the laser strikes, the resin solidifies into a thin layer. The build platform is then lowered slightly, and the process repeats, with each layer being added on top of the previous one. Once the printing is complete, the part is removed from the printer and rinsed in a solvent to remove any excess resin. The part is then cured using UV light to ensure that it is fully hardened. SLA offers ability to produce highly accurate and precise parts with smooth surfaces with intricate details and sharp angles that may be difficult to achieve with other methods.

Vacuum casting, pioneered by Tieckpak, is an advanced manufacturing technique used to create intricate and high-quality parts. With a focus on precision and versatility, Our vacuum casting process has gained recognition for its ability to produce complex components with exceptional surface finish and mechanical properties. We begin with the creation of a master pattern, typically made using 3D printing or CNC machining. This master pattern serves as the foundation for creating the mold. A liquid silicone rubber (LSR) material is carefully poured around the master pattern, ensuring it encapsulates all the intricate details. The LSR is then allowed to cure, resulting in a durable and flexible mold. Once the mold has fully cured, it is prepared for the casting process. A two-part polyurethane resin, often mixed with additives to achieve specific material properties, is measured and poured into the mold cavity. The mold is then securely clamped to prevent any leakage during the casting process. Then the item is placed in a vacuum chamber, the chamber is sealed, and the air is evacuated, creating a vacuum environment. This pressure differential allows the resin to flow evenly and efficiently throughout the mold, ensuring complete filling and minimizing the presence of air bubbles or voids.